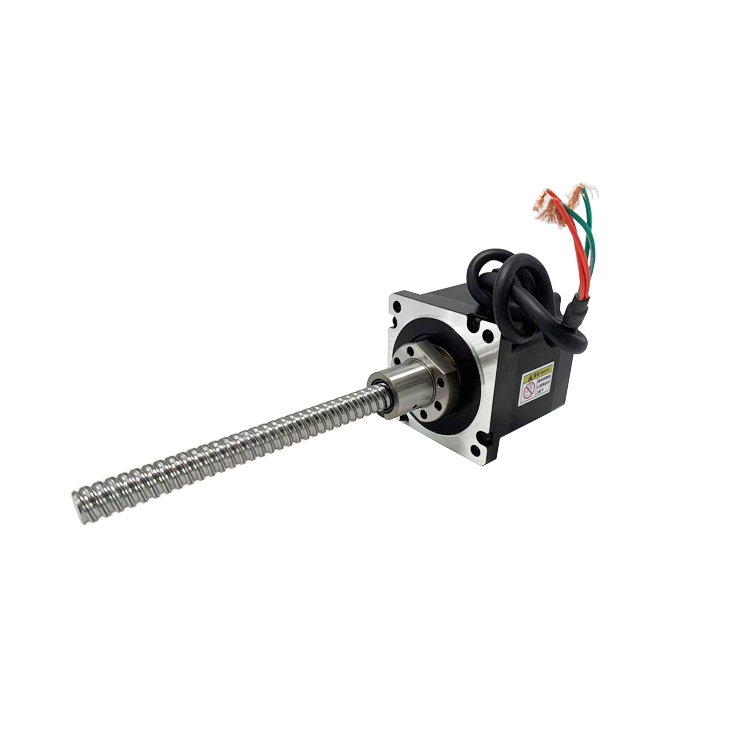

Motora gavavêtinê ya hîbrîd a Nema 34 (86mm) bi pêça topê 1.8° Goşeya Gavê 4 Têlên Serî Voltaja 3/4.8V Herikîna 6A

Terîf

| Navê Berhemê | Motora gavê ya pêça topê ya hîbrîd a 86 mm |

| Cins | VSM86BSHSM |

| Awa | motorên gavê yên hîbrîd |

| Goşeya Gavê | 1.8° |

| Voltaj (V) | 3 / 4.8 |

| Herikîn (A) | 6 |

| Berxwedan (Ohm) | 0.5 / 0.8 |

| Înduktans (mH) | 4 / 8.5 |

| Têlên Serî | 4 |

| Dirêjahiya Motorê (mm) | 76 / 114 |

| Germahiya Hawirdorê | -20℃ ~ +50℃ |

| Bilindbûna Germahiyê | 80K herî zêde |

| Hêza Dîelektrîkî | 1mA Max. @ 500V, 1KHz, 1 Sek. |

| Berxwedana Îzolasyonê | 100MΩ Kêmtirîn @500Vdc |

Motora gavavêtinê ya hîbrîd Nema 34 (86 mm), duqutbî, 4-serî, pêça gulî, dengê kêm, temenê dirêj, performansa bilind, sertîfîkaya CE û RoHS.

Motora gavavêtinê ya pêça gogê, bi karanîna pêça gogê, tevgera zivirî vediguherîne tevgera xêzikî; pêça gogê xwedî cûrbecûr kombînasyonên qûtre û seriyê ye, da ku hewcedariyên serîlêdanê yên cûda bicîh bîne.

Motora gavavêtinê ya pêça topê bi gelemperî di serlêdanên ku hewceyê tevgera xêzikî ya rastbûna bilind, temenê dirêj, karbidestiya bilind e, wekî otomasyona pîşesaziyê, cîhaza nîvconductor, û hwd. tê bikar anîn.

ThinkerMotion motorên gavê yên bi pêçên gulî yên tevahî (NEMA 8, NEMA11, NEMA14, NEMA17, NEMA23, NEMA24, NEMA34) bi rêjeya barkirinê ji 30N heta 2400N û pileyên cûda (C7, C5, C3) yên pêçên gulî pêşkêş dike.

Xwerûkirin dikarin li gorî daxwazê werin pêvajoy kirin, wek dirêjahiya pêç û dawiya pêç, gwîz, firna magnetîkî, kodker, û hwd.

Sertîfîkayên

Parametreyên Elektrîkî:

| Mezinahiya Motorê | Woltî/ Dem (V) | Vêga/ Dem (YEK) | Berxwedan/ Dem (Ω) | Înduktans/ Dem (mH) | Hejmara Têlên Serî | Bêçalakiya Rotorê (g.cm2) | Giraniya Motorê (g) | Dirêjahiya Motorê L (mm) |

| 86 | 3 | 6 | 0.5 | 4 | 4 | 1300 | 2400 | 76 |

| 86 | 4.8 | 6 | 0.8 | 8.5 | 4 | 2500 | 5000 | 114 |

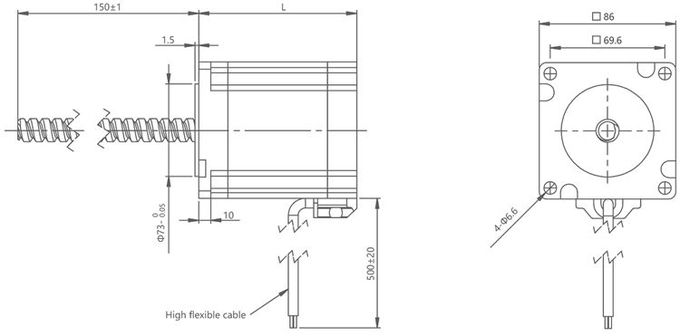

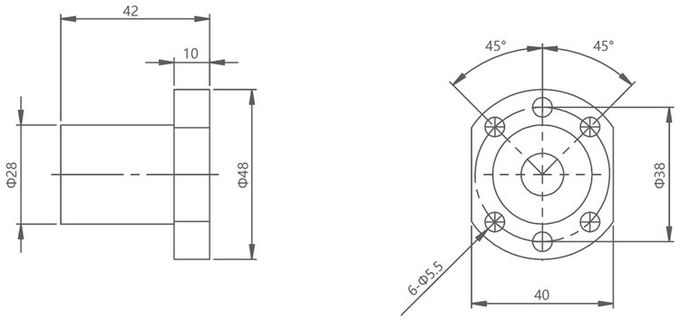

Nexşeya xêzkirî ya motora derveyî ya standard a VSM86BSHSM:

Têbînî:

Dirêjahiya pêça seriyê dikare were xweş kirin

Makînekirina xwerû di dawiya pêça pêşeng de maqûl e

Ji kerema xwe ji bo bêtir taybetmendiyên pêçên topê bi me re têkilî daynin.

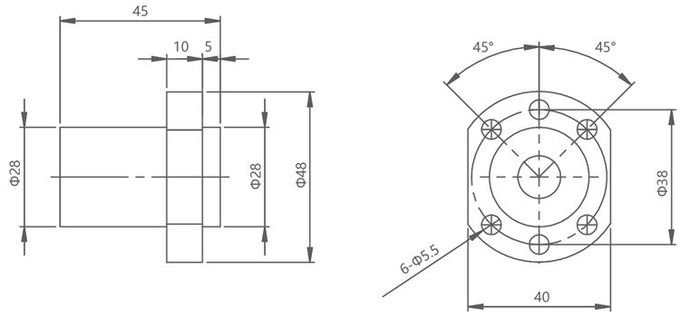

Nexşeya xêzkirî ya gwîza topê ya VSM86BSHSMB 1605

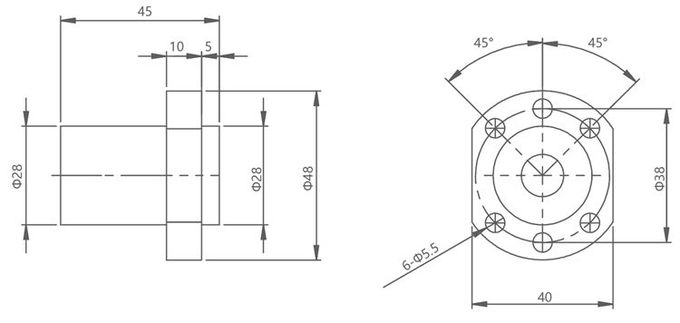

Nexşeya xêzkirî ya gwîza topê ya VSM86BSHSMB 1610

Nexşeya xêzkirî ya gwîza topê ya VSM86BSHSMBincî 1616

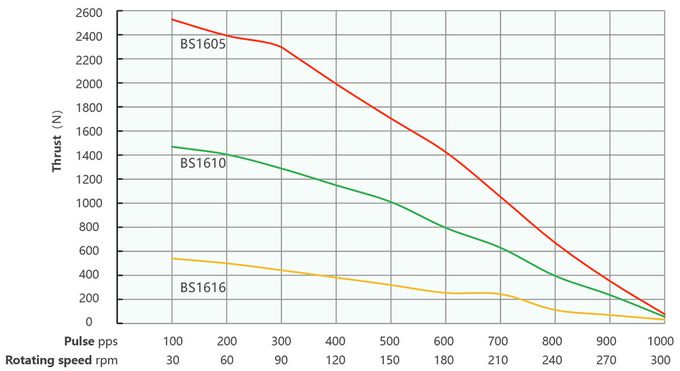

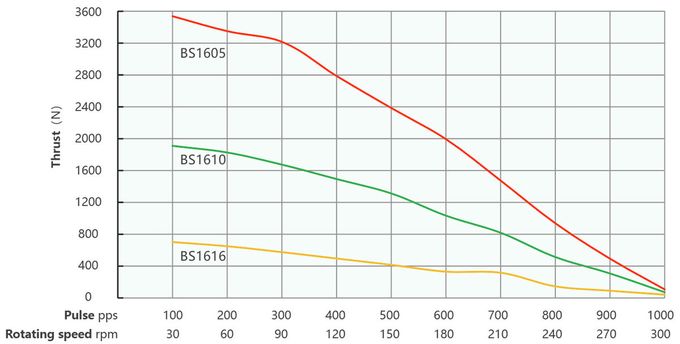

Xêza lez û bezê

Ajokera Chopper a duqutbî ya bi dirêjahiya motorê ya rêzeya 86an 76mm

100% frekansa pulsa niha û xêza kişandinê

Ajokera Chopper a duqutbî ya bi dirêjahiya motorê ya rêzeya 86an 114mm

100% frekansa pulsa niha û xêza kişandinê

| Serî (mm) | Leza xêzikî (mm/s) | |||||||||

| 5 | 2.5 | 5 | 7.5 | 10 | 12.5 | 15 | 17.5 | 20 | 22.5 | 25 |

| 10 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| 16 | 8 | 16 | 24 | 32 | 40 | 48 | 56 | 64 | 72 | 80 |

Rewşa ceribandinê:Ajokera chopper, bê ramping, nîv-mîkro-gav, voltaja ajotinê 40V

Qadên sepandinê:

Çêkirina Nîvconductor:Di pîşesaziya nîvconductoran de, rastbûn û pêbawerî pir girîng in. Motorên gavavêtinê yên hîbrîd ên 86 mm di alavên çêkirina nîvconductoran de, wekî pergalên desteserkirina waferan, makîneyên girêdana têlan, û pergalên hevrêzkirina rast de têne bikar anîn. Ew rastbûna pozîsyonê ya pêwîst û kontrola tevgera nerm a ku ji bo pêvajoyên çêkirina nîvconductoran hewce dike peyda dikin.

Makîneyên Pakkirin û Etîketkirinê:Pîşesaziyên pakkirin û etîketkirinê pir caran ji bo pêvajoyên pakkirinê yên bi bandor û pêbawer hewceyê pozîsyonkirina bilez û rast in. Motorên gavavêtinê yên pêçayî yên topê yên hîbrîd ên 86 mm di makîneyên pakkirinê, sepankerên etîketan û pergalên kartonkirinê de têne dîtin, ku tevgera rast û pozîsyonkirina pakêt an etîketan misoger dikin.

Amûrên Test û Pîvana Otomatîk:Di sepanên ceribandin û pîvandinê de, bicihkirina rast û tevgera kontrolkirî ji bo bidestxistina daneyên rast û ceribandinê girîng in. Motorên gavê yên pêçayî yên topê yên hîbrîd di alavên ceribandina otomatîk (ATE), makîneyên pîvandina koordînasyonê (CMM) û cîhazên din ên pîvandinê de têne bikar anîn da ku bicihkirina rast û dubarekirî ya sondaj, sensor, an pêkhateyên ceribandinê bi dest bixin.

Otomasyon û Robotîka Pîşesaziyê:Otomasyona pîşesaziyê xwe dispêre kontrola tevgerê û bicihkirina rast. Motorên gavavêtinê yên hîbrîd ên 86 mm di gelek pergalên otomatîk de, di nav de xetên montajê, robotên hilgirtina materyalan, wesayîtên rêberkirî yên otomatîk (AGV), û milên robotîk de roleke girîng dilîzin. Ew torka pêwîst, rastbûn û pêbaweriyê peyda dikin da ku karên dubare bi rastbûn pêk bînin.

Sîstemên Birrîn û Gravurkirina Lazerê:Makîneyên birrîn û gravurkirina bi lazerê ji bo afirandina sêwiranên tevlihev bi rastbûnek bilind hewceyê tevgerên rast û kontrolkirî ne. Motorên gavavêtinê yên pêçayî yên topî yên hîbrîd di van pergalan de têne bikar anîn da ku tevgera serên lazerê bimeşînin, û di dema pêvajoyên birrîn an gravurkirinê de tevgera xweş û rast misoger dikin.

Pakkirin û Birêvebirina Materyalan:Di sepanên ku pakkirin, rêzkirin û desteserkirina materyalan vedihewîne de, motorên gavavêtinê yên pêçayî yên topê yên hîbrîd ên 86 mm di pergalên konveyor, maseyên endekskirinê û milên robotîk de têne bikar anîn. Ev motor pozîsyonkirina rast û tevgera kontrolkirî ya pakêtan an materyalan gengaz dikin, û operasyonên desteserkirinê yên bi bandor û pêbawer misoger dikin.

Sîstemên Belavkirina Otomatîk:Serlêdanên belavkirinê, wek belavkirina bi lepik, dagirtina şilavê, an dozkirina rast, belavkirina rast û kontrolkirî ya şilav an madeyan hewce dike. Motorên gavê yên pêçayî yên topê yên hîbrîd di pergalên belavkirina otomatîk de têne bikar anîn da ku cîh û rêjeya herikînê kontrol bikin, û encamên belavkirinê yên rast û domdar misoger bikin.

Berjewendî

Rastbûna Pozîsyonê ya Hêja:Motorên gavavêtinê yên hîbrîd ên bi pêçên gogê ji ber taybetmendiyên xwerû yên mekanîzmaya pêçên gogê rastbûna pozîsyonê ya hêja pêşkêş dikin. Meclîsa pêçên gogê paşvekişandinê kêm dike û dubarebûnek bilind peyda dike, ku pozîsyona rast a şaftê motorê misoger dike. Ev rastbûn di sepanên ku hewceyê kontrol û pozîsyona tevgerê ya rast in de girîng e, wekî makîneyên CNC, çapkerên 3D, û pergalên vekolîna otomatîk.

Kapasîteya Xwe-Qefilandinê:Yek ji avantajên girîng ên motorên gavavêtinê yên hîbrîd ên bi pêçên gogê, şiyana wan a xwe-kilîtkirinê ye. Mekanîzmaya pêçên gogê xwedî karîgeriyeke mekanîkî ya bilind e, ku dihêle motor bêyî ku hewcedariya bi hêzek domdar hebe, pozîsyona xwe bigire. Ev taybetmendî di sepanên ku dema motor bi awayekî çalak nayê xebitandin de hewce ye ku pozîsyonek were girtin an jî tevgera nexwestî were astengkirin de sûdmend e.

Tîrbûna Torkê ya Bilind:Motorên gavavêtinê yên hîbrîd ên 86 mm dendika torkê ya bilind pêşkêş dikin, ku dihêle ew ji bo mezinahiya xwe derana torkê ya girîng peyda bikin. Ev di sepanên ku motorên kompakt ên bi kapasîteyên torkê yên bilind hewce ne de avantajek e, wekî movikan robotîk, manipulatorên pîşesaziyê, û pergalên kontrola tevgera torkê ya bilind.

Rêzeya Leza Berfireh:Motorên gavavêtinê yên hîbrîd ên bi pêçên topî dikarin li ser rêzek fireh ji lezayan bixebitin, ji leza nizm ji bo sepanên torka bilind bigire heya leza bilind ji bo karên pozîsyonkirina bilez. Ew dikarin kontrola leza rast bi dest bixin û li seranserê rêza xebitandinê aramiyê biparêzin, ku wan ji bo sepanên ku hewceyê şiyanên leza piralî ne, wekî pergalên hildan-û-cihkirinê, xetên montajê yên otomatîk û makîneyên tekstîlê guncan dike.

Bikaranîna wê hêsan e û bi arzanî ye:Motorên gavavêtinê yên hîbrîd ên bi pêçên topî nisbeten hêsan têne sazkirin û bikar anîn. Ew di pergalek kontrola çerxa vekirî de dixebitin, û hewcedariya bi cîhazên bersivê yên zêde yên wekî kodkeran ji holê radikin. Ev yek sêwirana giştî ya pergalê hêsan dike û lêçûnan li gorî pergalên servo yên çerxa girtî kêm dike. Kontrola motora gavavêtinê bi gelemperî bi rêya sînyalên puls û rêwerzê tê bidestxistin, ku entegrasyonê bi pergalên kontrolê re hêsan dike.

Baweriya Bilind û Berxwedana Bilind:Motorên gavavêtinê yên hîbrîd ên bi pêçên gogê bi pêbawerî û domdariya xwe ya bilind têne nasîn. Mekanîzmaya pêçên gogê tevgera nerm û domdar peyda dike, xişandinê kêm dike û temenê motorê dirêj dike. Wekî din, ew kêmtir meyla sekinandin an windakirina gavan dikin, ku di sepanên dijwar de xebitandina pêbawer misoger dike.

Parastina Kêm:Bi sêwirana xwe ya xurt û performansa xwe ya pêbawer, motorên gavavêtinê yên hîbrîd ên 86 mm hewceyê lênêrînê ya herî kêm in. Meclîsa guhêrbar bi gelemperî tê rûnkirin û mohrkirin, ku hewcedariya bi karên lênêrînê yên dubare yên wekî ji nû ve rûnkirin an ji nû ve rêzkirinê kêm dike.

Pêdiviyên Hilbijartina Motorê:

►Arasteya tevgerê/çûnê

►Pêdiviyên Barkirinê

►Pêdiviyên Lêdanê

► Pêdiviyên makînekirinê yên dawî

►Pêdiviyên Rastbûnê

►Pêdiviyên Bersiva Koderê

►Pêdiviyên Rêkxistina Destî

► Pêdiviyên Jîngehê

Atolyeya hilberînê